通知设置 新通知

焊接技术公司K-TIG成功签约英国核能先进制造研究中心 Nuclear AMRC

martinpl 发表了文章 • 0 个评论 • 450 次浏览 • 2019-12-11 08:06

Welding & materials

Welding R&D at the Nuclear AMRC focuses on developing advanced and innovative joining and cladding techniques tailored to the needs of the nuclear industry.

Many key components in a nuclear power plant must be manufactured by joining very large sub-components in a way that resists corrosion and maintains material integrity under extreme in-service conditions.

Welding on this scale can be a complex task – a single joint between thick-walled nuclear components might require over 100 weld passes using standard techniques. The repeated heating and cooling can have significant effects on the material properties around the join, potentially harming the long-term performance of the component.

Our welding team has the resources and experience to help companies develop new and optimised welding processes for the most demanding applications. We are also investigating and developing a variety of materials engineering processes, including hot isostatic pressing and bulk additive manufacturing, for nuclear applications.

For more information about our welding capabilities and research, contact Will Kyffin, acting head of welding.

Current equipment at our South Yorkshire facility includes:

Pro-Beam K2000 EBW chamber

- Very large electron beam welding chamber with range of advanced features, for joining and additive manufacturing of vessels and components.

- Volume of 208 cubic metres, the largest of its kind in the UK, max part weight 100 tonnes.

- Internal mobile 40kW 80kV gun.

- Able to produce fully penetrated single-sided welds up to 150mm thickness in steel.

- Fully automatic joint following and variable thickness programming, available on only a small number of machines worldwide.

- Nine axes of movement.

- Research into bulk additive manufacturing.

Pro-Beam K25 EBW chamber

- Electron beam welding chamber for pilot research into innovative joining techniques for large components.

- Chamber volume of 2.5 cubic metres, max part weight 500kg.

- Static 40kW 80kV electron beam gun.

- Welding of plates up to 100mm wall thickness, plus tubes and complex structures.

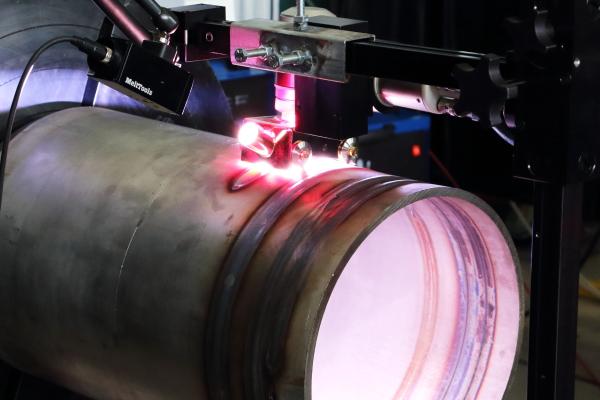

Diode laser cell

- High-speed, high-quality, low-waste cladding of large components with stainless steel, nickel alloys and wear-resistant alloys.

- 15kW Laserline fibre-coupled diode laser, capable of depositing up to 10kg/hour.

- Enclosed chamber measuring 10 x 10 x 5 metres.

- Roller turntable with max workpiece 3 metres diameter, 3.5 tonne load.

- Small-bore cladding capability, down to 70mm inner diameter and 400mm stroke.

- Welding of steel up to 10mm thickness.

- Research into bulk additive manufacturing and five-sided welding techniques.

Disk laser cell

- High-speed, high-quality welding of large components.

- 16kW Trumpf fibre-coupled disk laser, mounted on six-axis gantry system.

- Enclosed chamber measuring 10 x 7 x 8 metres.

- Turn/tilt table for workpieces up to 3 metres diameter, 15 tonne load.

- Autogenous or wire-fed laser welding.

- Laser-hybrid welding.

- Cutting for decommissioning.

ITW Miller SAW cell

- Flexible submerged arc welding cell for conventional narrow-groove, circumferential and longitudinal welding.

- 15 tonne manipulator under 5 x 5 metres column and boom, supplied by ITW Miller.

- Range of heads, including strip clad welding head capable of welding 90mm strip.

- R&D focuses on optimising conventional welding processes for nuclear applications.

Polysoude GTAW cell

- Multi-function gas tungsten arc welding cell offering choice of heads for wide range of applications.

- Polysoude 7.5 tonne manipulator on 6 x 4 metres column and boom.

- Can deploy variety of end effectors, on tractor unit with three axes of movement. Heads include dual hot and cold wire; narrow gap; extremely narrow gap; and keyhole welding.

- Polycar track system allows welding where column and boom can’t reach.

- Research focuses on optimising conventional welding processes for nuclear applications; and groove welding for components, such as set-in nozzles and bosses, within the nuclear island.

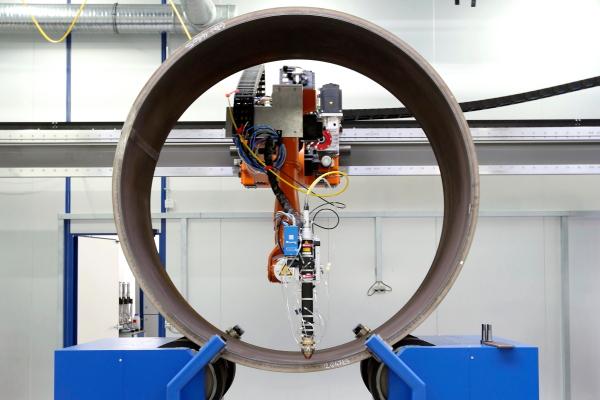

ABB/Fronius robotic welding cell

- Flexible robotic arc welding cell with additive and cladding capabilities.

- Fronius TPS 400i MIG/MAG welding system, with cold metal transfer function for high-speed cladding with minimal heat input.

- ABB IRB2600 six-axis robot arm and two-axis workpiece positioner with Absolute Measurement System.

- Research focuses on automated welding and cladding processes, real-time weld process monitoring, and additive manufacturing.

K-TIG 1000 keyhole welding

- High-speed single-pass full-penetration GTAW system for tubes, pipes and other fabrications.

- Welding speeds up to 100 times faster than conventional GTAW.

- Full automation with no need for filler wire, edge beveling or skilled operators.

- Can join metals including stainless steels, titanium, zirconium, Inconel and other specialist alloys.

ESAB planetary SAW

- ESAB A6-MHW submerged arc welding system designed for joining nozzles and access hatches to cylindrical vessels or flat plates.

- Can weld nozzles of 150-1,100mm diameter and 150-750mm height.

- Slip ring allows continuous weld through repeated rotations, with high deposition rates significantly reducing weld time.

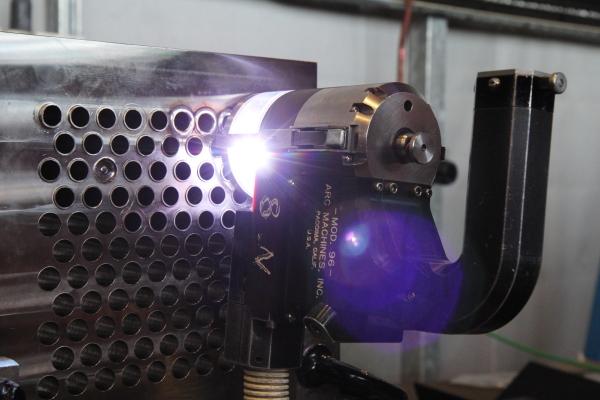

AMI tubesheet welding cell

- Specialised GTAW cell for autogenous welding of tubes and tubesheets.

- AMI Model 96 and Model 6 weld heads with AMI Model 227 power source.

- Fully portable solution for fabrication of heat exchanger assemblies.

- Pneumatic clamping system ensures that weld heads are optimally positioned before welding.

AMI narrow groove welding cell

- Orbital welding cell for large and small diameter narrow groove weld preparations.

- AMI Model 52 narrow groove welding head with AMI Model 415 power source, offering high integrity GTAW process.

- Used without traditional column and boom, ideal for portable welding projects.

Bulk additive manufacturing cell

- Robotic cell capable of building high-integrity parts from the ground up, and adding metal features to large forgings such as pressure vessels.

- Robot works directly from CAD model to lay down weld material to create three-dimensional geometries.

- 10 x 5 metres cell with a six-axis Kuka robot arm, mounted on a three-axis 9 metre gantry, plus a two-axis manipulator with turntable of 3.5 metres diameter.

- Initially fitted with ‘toptig’ arc welding system, which integrates the wire feed into the welding torch, developed by Air Liquide specifically for robotic welding applications.

Quintus hot isostatic pressing facility

- Densification of cast or additive parts, and consolidation of metallic powders to produce near-net shape components.

- Hot zone of 450mm diameter by 1300mm length, workload up to 1 tonne.

- Temperature up to 1450°C, pressure up to 207MPa (30,000psi).

墨尔本羊奶粉公司Nuchev 上涨30% 开盘

martinpl 发表了文章 • 0 个评论 • 186 次浏览 • 2019-12-09 12:32

墨尔本企业nuchev , 开盘30%, 3.4 元每股开盘。ipo价格2.6澳元每股

其价格已经企稳

“先购买后付款”公司Sezzle获得1亿美元更低成本债务融资

martinpl 发表了文章 • 0 个评论 • 225 次浏览 • 2019-12-02 09:40

“先购买后付款”公司Sezzle获得1亿美元更低成本债务融资

“先购买后付款”提供商Sezzle Inc.(ASX: SZL)收到与美国三家机构签订了新的债务融资协议,获得了1亿美元资金以支持该公司在北美市场的增长。股价开盘升7.5%。

美国和加拿大市场的“先购买后付款(BNPL)”提供商Sezzle Inc.(ASX: SZL) 获得了来自美国信贷提供方的1亿美元债务融资,以使Sezzle能够在向这些最终客户收取货款之前向零售商户客户付款。

新的债务融资由Atalaya Capital Management、Bastion Consumer Lending和Hudson Cove Capital Management三家机构提供,他们均为资产管理公司,专门从事消费者贷款和替代信贷。

利用外债融资是Sezzle为最终客户购买提供资金的一个关键方法。截至2019年9月30日的12个月期间,Sezzle为潜在商户的1.575亿美元销售额提供了资金,其中部分资金来自Bastion提供的3000万美元Prior Facility。

Sezzle表示,公司在北美BNPL市场看到了巨大的增长机会,并因此与三家信贷提供者签署了新的贷款协议,以充分利用这些机会。Sezzle先前贷款的大幅增加是其增长战略的关键所在,而1亿美元的债务融资使Sezzle能够继续积极发展公司业务。

Sezzle首席财务官Karen Hartje表示,“这笔资金的成本要比此前的Prior Facility更优越。”

Sezzle执行主席兼首席执行官Charlie Youakim认为,新的贷款协议不仅扩展了公司与Bastion Consumer Funding的现有关系,而且还将Atalaya Capital Management和Hudson Cove Capital Management引入为公司的新合作伙伴,从而使该公司的债务融资关系更加多样化。这些合作伙伴所提供的流动性的大幅增加将巩固Sezzle扩大向消费者提供产品的能力,从而提高公司潜在商家的销售。”

企业贷款公司Prospa利润预期下调62%,股价三天暴跌50% ,破发

martinpl 发表了文章 • 0 个评论 • 204 次浏览 • 2019-11-22 11:17

企业在线贷款商Prospa利润预期下调62% 股价破发

小型企业在线贷款商Prospa Group (ASX: PGL) 下调全年收入预期,收入下调8%,利润下调62%。公司的优质化战略或为主要原因。

小型企业在线贷款商Prospa Group Limited(ASX: PGL) 预计,公司2019年全年收入将约为1.438亿澳元,同比增长16%,但较招股书中的1.563亿澳元下降8%。息税折旧摊销前利润减少至400万澳元,较此前预期的1,060万澳元低62%。Prospa认为这一差异主要与公司的优质化战略有关。

(招股书指引与调整后的指引对比)

(招股书指引与调整后的指引对比)

截至2019年10月31日,Prospa在财年前四个月的贷款发行量为1.812亿澳元,同比增长40%。自2012年成立业务以来,Prospa已发放了13.5亿澳元的小企业贷款。在Prospa继续向所有信用等级增加贷款的同时,信用质量较高的客户需求不断增加。

公司的投资组合中约有43%是发放给优质客户的贷款。虽然优质客户对公司的市场渗透、经营杠杆、融资多样性和投资组合弹性产生了积极影响,但却对短期收入产生了负面影响。因为这些客户长期支付较低的利率。

截至2019年10月31日的四个月数据显示,向优质客户提供的贷款利率低于平均账面利率,并且贷款期限更长。Prospa账面上的平均单利已调整为18.5%(招股书预测为18.9%),平均贷款期限已增加至14.6个月(招股书为14个月)。

对此,Prospa的联合创始人兼联合首席执行官Greg Moshal强调,“尽管预期收入受到短期影响,但我们对增长策略的正确性很有信心。 随着早期损失指标继续呈现出改善的趋势,公司将继续投资于新产品、销售和营销。”

此外,较低的基准利率和更多一级银行高级融资将继续对Prospa的盈利能力产生积极影响。公司预计,2019年全年的融资成本将降低至1,880万澳元,低于招股书预期的2,120万澳元。

贝拉米通过FIRB批准-蒙牛收购成功

martinpl 发表了文章 • 0 个评论 • 453 次浏览 • 2019-11-15 12:08

2019年11月15日奶粉及儿童辅食供应商 贝拉米澳大利亚有限公司(Bellamy)(ASX: BAL) 宣布,外国投资审查委员会(FIRB)今天已向中国蒙牛乳业有限公司发出书面通知,联邦政府不反对蒙牛全资子公司通过协议安排收购贝拉米公司。

计划的实施仍然受许多条件的约束,包括贝拉米股东在计划会议上的批准、法院的批准,以及其他协议安排中所提及的惯例条件。

贝拉米董事会继续建议贝拉米的股东在2019年12月5日(星期四)上午10:00(澳大利亚东部标准时间)举行的计划会议上投票赞成该计划。董事会认为该计划符合贝拉米股东的最大利益。

2019年9月16日,贝拉米发出公告称,中国蒙牛乳业有限公司 (SEHK:2319 Mengniu) 将以约15亿澳元收购其100%股权。根据双方签署的计划实施契约(Scheme Implementation Deed),贝拉美股东将获得每股13.25澳元现金的对价,其中0.6澳元作为特别股息。

这个收购价格是2019年9月13日贝拉米收盘价8.32澳元的159% ,以及过去三个月成交量加权平均价8.59澳元的154% 。按现金收购价估值,贝拉米的100% 股权价值约15亿澳元。这个数目的企业价值是贝拉米标准化2019财年息税折旧摊销前利润(EBITDA)——4,690万澳元的30倍。

(贝拉米有机系列产品之一)

(贝拉米有机系列产品之一)

对于这项收购案,贝拉米的首席执行官Andrew Cohen表示:“蒙牛是中国一家卓越的乳品公司,也是我们业务上的理想合作伙伴。这次合作为澳大利亚有机乳制品和食品行业提供了一个在中国的强大分销平台,这是澳洲乳品业发展的基础。 ”

Andrew Cohen先生认为此次交易可以进一步实现贝拉米创始人的景愿——推广真正标志性的澳大利亚品牌。

蒙牛的首席执行官Jeffrey Minfang Lu先生评论:“贝拉米是一个领先的澳大利亚品牌,源自塔斯马尼亚的传统,并为澳大利亚父母提供高品质的有机产品。这个领先有机品牌和贝拉米的本地运营和供应链对蒙牛来说至关重要。 ”

有关贝拉米

贝拉米是全球公认的澳大利亚有机品牌企业,但并非主要生产商。公司于2014年在塔斯马尼亚成立并在澳大利亚证券交易所上市(股票代码:BAL),为婴儿和幼儿生产、供应和销售一系列有机食品和婴儿配方奶粉。贝拉米的原料来自澳大利亚和国际供应商,产品足迹覆盖澳大利亚、越南、新加坡、马来西亚、新西兰和中国(包括中国特别行政区香港),以及通过在线平台在各国分销。贝拉米在澳大利亚、中国和新加坡拥有约160名员工。

有关蒙牛乳业

蒙牛是中国领先的乳制品生产商之一,在香港证券交易所上市(股票代码:2319),市值约为246亿澳元,其69%的股权由公众投资者拥有。 在2017年和2018年,蒙牛在Rabobank出版的“全球乳品20强”排行榜中名列乳品行业前10名。

蒙牛及其子公司在中国生产和销售高品质乳制品,并在新西兰和印度尼西亚设有生产基地。 蒙牛还通过其海外销售网络将其乳制品分销到香港、新加坡、澳门、缅甸和印度尼西亚。

REA 集团2019 FY1业绩下降

martinpl 发表了文章 • 0 个评论 • 273 次浏览 • 2019-11-08 09:16

全球在线房地产广告公司 REA集团昨天公布了其2019年上半年的数据

收入下降9%, EBITDA 下降14%, 同比下降20%

虽然最近房价稍微回升,但整体来说还是不尽人意的

The recent housing bounce hasn’t flowed through to REA, the company saying this morning that the market remains challenging and 1H20 listings volumes to be lower than H1FY19.

Rev down 9%, EBITDA down 14% and FCF -20% on 1Q19.

澳洲羊奶粉品牌Nuchev寻求上市

martinpl 发表了文章 • 0 个评论 • 338 次浏览 • 2019-11-05 08:21

据悉,澳洲羊奶婴幼儿奶粉生产商,Nuchev 开始展开IPO Roadshow,将从澳洲、新西兰和亚洲募集资金。

该公司旗下主要为品牌名为Oli6羊奶配方奶粉,据悉主要销往中国和澳洲本土,两地各占一半销售额。

创始人及CEO为Ben Dingle,was a co‐founder of New Zealand’s Synlait Milk。

新闻显示,该公司曾在2017年10月传出欲IPO上市。

Sole lead manager and underwriter is Wilsons.

2019年5月31日,澳洲奶粉品牌Oli6顺利完成3000万澳币的融资,并宣布,计划在6个月内于澳大利亚证交所(ASX)上市。

暂无详细信息,IPO融资可能在4000万澳元左右。EV可能在1.08-1.62亿澳元。

Nuchev的 直接竞争对手是羊奶粉品牌 BuBs Australia 和已经被蒙牛集团邀约收购的品牌贝拉米